Technically, there is no such thing as an XPR. As far as the FAA is concerned, any XPR remains a 400A (there are technically no 400XPs. All XPs are just 400As). An XPR is simply a Beechjet that has a series of STC conversions done to an original Beechjet that dramatically improve the capabilities and ramp appeal of the aircraft. I’ll expand on each of these items in the following paragraphs.

1. Removal of the original JT15 engines and replacing them with Williams FJ44-4A engines;

2. Addition of the Textron Winglets (and the associated wingtip LED lights);

3. Replacement of the original (and obsolete) Proline 4 avionics with either Proline 21 (the original option, but no longer available), or a Garmin G5000 (the modern solution);

4. Refurbished interior; and,

5. Additional maintenance items that get completed, depending on the maintenance status of the aircraft. Some maintenance items may have been completed early.

Engines

The original JT15 engines used on the Beechjet were par for the course and, to be honest, an expectation, when the Beechjet was first developed by Mitsubishi. All business jets of this thrust class used some variant of this engine at the time, including the Citations. In these early days, the only other options would have been a PT6 turboprop engine or the TFE731, neither of which are really in the thrust/power class of the JT15. Competition was low, and engine selection was purely dictated by the thrust or power requirements of the aircraft. Interestingly enough, some flight testing was conducted with early Citation jets using PT6 pusher engines and some King Airs using JT15 engines (See photos, below).

Figure 1 - A Citation with PT6 Engines

Figure 2 - A King Air with JT-15 Engines

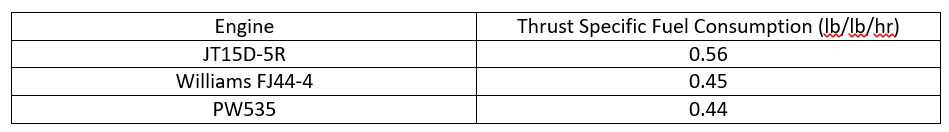

By the 1990s, the JT15 was no longer the only player in the thrust class demanded of by light jets. Williams had introduced their FJ44 series for the CJ line, and the PW535 series engine was introduced on the Encore and, a little later, on the Phenom 300. The thrust specific fuel consumption of these later engine entrants to this thrust class were significantly better than the older technology JT15, while still producing more thrust.

If you do the math on these TSFCs, you’ll notice that the FJ44 and the PW535 have a nearly 20% improvement compared to the older JT15D engines.

Beechjet production ended in 2009 because of the collapse of the American economy as a result of the popping of the housing bubble and failure of several large investment banks in 2008. Prior to the ending of the Beechjet program, the engineers at Hawker-Beechcraft had been working on a successor to the design which would take advantage of the increased efficiency of the PW535. This successor was named the Beechjet 450. Although data is sparse on the 450, it seems that the only major change was the use of the PW535 to replace the JT15. This aircraft never saw production.

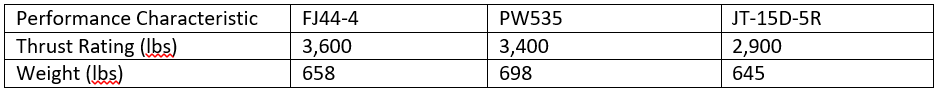

When developing the XPR, the engineers at Textron decided to go with the FJ44 engine choice. Why they went this direction vs the PW535, we’ll never really know. Perhaps it was because the FJ44-4A, which was used on the XPR, had a slightly higher thrust rating than the PW535. It could have also been related to the difference in maintenance requirements. The idea could have also been a purely political decision based on deals offered by the engine manufacturers. Both the PW535 and the FJ44 have full FADEC engine controls, whereas the JT15D utilizes an EFC, which you can say is a “poor mans FADEC.” A comparison of the engines is below.

The FJ44-4A engine is a major improvement over the original JT15D. The retrofit of this engine is made legal through the use of an STC developed by a now defunct company bought out by Textron called Sierra Industries. All of the technical documentation specific to the engine retrofit is labelled under the Sierra Industries logo.

Although capable of producing 3,600lbs of thrust, the engineers opted to flat-rate the engine to only 3,200lbs. of thrust at 17C. What does this mean? It means that although you don’t get the full benefit of the full 3,600lbs of thrust at sea level, you get to take advantage of being able to maintain the 3,200lbs. of thrust you are allowed to a higher altitude. If left at the 3,600lbs thrust limitation, the aircraft would immediately see a reduction in available thrust as it climbs as the air gets thinner. By flat-rating to 3,200lbs. of thrust, the engine will be able to maintain the 3,200lbs thrust rating for longer as the aircraft climbs into thinner air. Eventually, the air will get so thin that you will see a thrust decrease even with the flat rating. The flat rating results in significantly improved climb performance because the engine is capable of maintaining rated thrust for longer while not adding too much additional thrust stress to the airframe’s structure. You’ll see this when we discuss flying the XPR and how this really increases the fuel efficiency of the aircraft.

Note that the XPR does not have any thrust reversers. Although they are an option for Williams FJ44 engines, they are not installed and not certified. There is no landing penalty for this, however, you will see a performance hit with takeoff runway requirements because they took advantage of the reversers during the certification of the aircraft during the aborted takeoff portion. More on this later.

Winglets

All XPRs are equipped with winglets These are the Textron Winglets that replace the original Beechjet wingtips and blend seamlessly with the wing structure. The navigation and strobe lights that are originally located in the wingtips are replaced with a new external LED light assembly located on the outside of the winglet. These lights are practically maintenance free and have a service life that can practically be considered indefinite.

The winglet is not simply bolted on to the end of the wing. The installation of the winglet is an involved process that involves structurally modifying the wing to accommodate the winglet. Keep this in mind if you’re towing your aircraft or trying to squeeze it into a hanger that is tight. The winglets add a few feet in width to the aircraft compared to a normal Beechjet, and this can cause quite a bit of headache if you purchase an XPR (or any Beechjet with Textron winglets) with the expectation that it’ll fit in the hanger based on the standard Beechjet dimensions.

The first thing to keep in mind with the winglets are that although the leading edge might be a polished metallic surface similar to the leading edge of the rest of the wing, it is not deiced like the rest of the leading edge. This means that you have no protection from ice accretion on the winglet should you enter icing conditions in flight. We’ll go into more detail on this when we get to flying the XPR.

The second thing to know about the winglets is that you get no book data in regards to a performance increase with the aircraft. I have flown traditional Beechjets with these winglets installed and have found that you do get a couple percent improvement in most performance categories, including rate of climb and perhaps a small decrease in cruise fuel consumption. The biggest benefit I notice when flying with the winglets is that the aircraft is slightly more stable in yaw than without.

Avionics

Originally when the XPR was introduced, Proline 21 was the avionics upgrade offered to replace the aging Proline 4 avionics suite. As time has progressed, the Proline 4 system has practically entered obsolescence and Proline 21 has also started its move towards the way of the Dodo bird. It is no longer possible to add Proline 21 to the Beechjet (although you may find the STC to do so advertised quite heavily, including the ability to extend the TBO of the original JT15D to 5400hrs. vs the original 3500hrs.). The only retrofit option that currently exists (and the only one you particularly want), is the G5000 retrofit option for the Beechjet. The aircraft I fly (whether an XPR or normal Beechjet) all have the G5000, and I highly recommend it.

The G5000 provides about a 200lb weight reduction compared to the original Proline 4 or Proline 21 option. The screens are larger and higher quality, the radar is better, and the pedestal controllers (FMS units, if you will) are much better to work with than the older Collins units.

The G5000 is capable of working with the XPR conversion, and it can easily display all engine parameters (limits) and fuel flow indications correctly. It seems half the XPRs have Proline 21 and half have Garmin. I look forward to the day that all have been converted to G5000.

Interior Refinements

All the XPRs got refreshed interiors during the upgrade. RK-467 has a beautiful interior with modern seats and cockpit controls (heat and light controls). The aircraft has a full cabinet in the front of the cabin. Wifi was normally added during the modification.

Additional Maintenance

Many XPR aircraft underwent substantial maintenance during the modification because it was convenient to do so while the aircraft was already down for the service. There seems to have been little logic to what was done to each aircraft, so you’ll need to scrutinize each aircraft’s logbooks and assess what was done by referencing the lengthy XPR conversion entry. RK-467 received a full D-Check while in for the conversion, although the legal 5000hr. requirement was over 1000hrs away. Oddly enough however, they didn’t complete a landing gear overhaul…

----

Home -- Aircraft Sales -- Contact Us