The Beechjet XPR, because it is simply a group of STCs, retains much of the original inspection program of the original Beechjet. We are still bound by the basic A, B, C and D inspection program, and then a series of special inspections that have unique time and calendar limitations. Note that on this page, we ignore the availability of alternate approved inspection programs.

Each STC comes with a variety of supplements. These include AFM supplements, maintenance manual supplements, structural maintenance manual supplements, wiring diagram supplements, parts manual supplements, etc. Each of these documents should be kept with the aircraft logbooks. For our airplanes, we have scanned and digitized these supplements and additions. This makes them readily available for when we need them, but also makes them readily searchable. I recommend you do the same. The AFM supplements need to be made available in the aircraft at all times.

Our XPRs are all on electronic maintenance tracking. With any jet of this size, its a good idea to get your enrolled if its not. If you don't want to pay the fee, you could develop your own electronic maintenance tracking system. I don't see a practical way to manage a paper maintenance tracking system. Either way you approach it, it remains your responsibility to stay on top of maintenance schedule changes. Yes, they happen. Textron still actively supports the Beechjet and the XPR, so you will get updates from time-to-time (particularly SBs and ADs). Within the past year we have recieved an updated checklist from Textron! You never know when they'll improve things.

PRSOVs

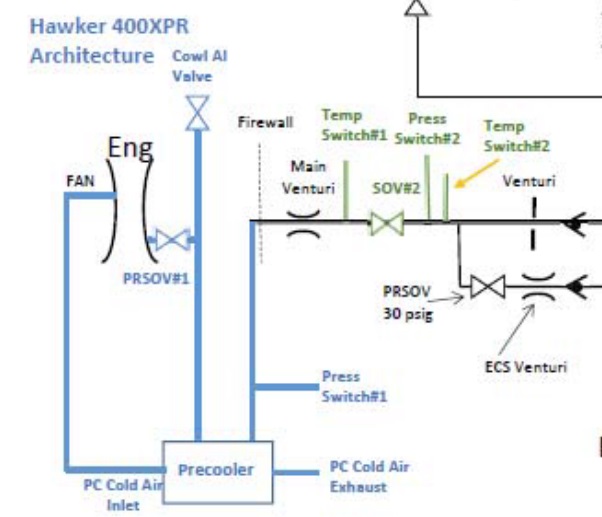

If there is one big difference between the normal Beechjet and the XPR, its the additional inspection requirements associated with the PRSOVs on the engines. The XPR has a refined bleed air system with more valves and sensors involved to handle the large amount of air coming from the Williams engines. For those who might be newer to jets, PRSOVs are pressure Regulating Shutoff Valves. As their name implies, both are valves that can open and close based on temperature and pressure inputs. They act to protect the bleed air system from too much hot temperature, high pressure air from going through the system, particularly at high power settings. They can also be used to manage the pressure in the system during low power settings.

These valves have caused operators quite a bit of consternation over the past few years. Luckily, Textron has been responsive on the issue and appears to be working to relax the inspection requirements and provide some relief to operators who have been struggling with it.

The first PRSOV inspection is a visual inspection. This is the easy part. The next inspection is a little more in depth: the functional check. It's a little more detailed than a simple operational check. You'll need to develop a special test aparatus (instructions are included in the maintenance manual supplement) and do a little bit of wiggling in the back of the airplane to make all the connections that you need to make.

The functional check is broken down into 4 different sections, and you need to check and pass all sections to have a good functional check:

1. Temperature Switch Verification - You will remove temp sensors from the system and apply heat to them using a test rig. At certain temperatures, you will check that the PRSOV and SOVs open and close.

2. Pressure Switch Verification - Similar to above, except we check the pressure sensors and the action of the PRSOVs and SOVs.

3. Opposite Engine Bleed System Circuit Crossover Redundancy - This check verifies that opposite side power can open and close the valves in the event of a power loss to one side. We do this by pulling the breaker to one side's bleed air system, and then trigger events that should close the valves. We check the voltage to the valves during the check to ensure proper power distribution.

4. Inflow Shutoff Timing - This check ensures that the system will manage bleed air so as not to overwhelm the existing bleed air system architecture associated with the 400A's systems, such as the ACM PRSOV and Anti-Ice PRSOV.

This seems like a lot, but it is a methodical check of the entire system. The hardest part of the check is getting to all the sensors. Some mechanics have determined they need to pull the entire ACM to get the access you need. This is not in the procedure. With a little creativity we seem to be able to get the check done successfully without going to such extremes.

What is more onerous for operators is not so much the functional check (though the functional check causes some consternation considering accessability issues and time it takes to work through all the steps in the check), but rather the PRSOV manufacturer inspection that is due every 200hrs. When part supply chains are working, Textron maintains a good supply of valves on exchange that allows us to quickly send in cores for exchange when this inspection comes up and get back flying. Count on $6k or so to exchange both valves. Not cheap, but cost of business with this plane. I have heard rumors Textron is working on lengthening this inspection requirement, which would reduce hourly costs significantly for operators.

What really caused problems that resulted in a lot of unsatisfied XPR owners was a disappearance of the valve rotable pool, killing the ability to do exchanges. Lead times for the valve exchange was 3-6 months at one point. It is possible to buy new valves, but you're looking at about $26k per valve for this purchase. Hardly is this an economical solution every 200 hours. Textron has done well increase the rotable pool size, and hopefully they continue to do so. To handle past issues, We have purchased a spare valve to go on the shelf that's ready to go. Our PRSOVs are staggered so we have one due for the 200hr inspection every 100hrs. We never have downtime with the extra valve on the shelf, while allowing us the ability to eat a lead-time to get valves inspected if the rotable pool dries up in the future.

To summarize, the PRSOV system of the XPR has slightly more inspection work than a normal Beechjet in the form of onboard visual and functional checks as well as a core inspection at Dukes (the original manufacturer). Textron is working with operators on dealing with these special inspections, although they seem less capable of doing the functional check than you would expect of a service center (probably stemming from the fact that even they rarely conduct the check).

If your mechanic is new to XPRs, it will take an investment in developing the tooling to do the tests and an investment in time to understand the steps and learning how to effectivly do them. This is a worthy investment. Having a local tech who is experienced with these regular PRSOV functional checks is a major advantage when it comes to operating the XPR economically.

Windshields

This isn't so much an XPR problem, but a Beechjet problem. Windshield delamination is a problem throughout the fleet, and PPG has been lagging in keeping up with demand for replacement windshields.

There are two ways for a windshield to fail and require replacement:

1. Delamination gets so bad that it impedes the pilot's field of vision (this is a common sense one; and,

2. Failure of the resistance check given in the maintenance manual.

There is a lead-time for windshields so I recommend staying on top of the condition of yours and being proactive about replacement. They're not cheap to buy, and not cheap to get installed, but running the risk of having a windshield catastrophically fail at an outstation is not worth the risk. Not only will you be stranded, your plane will be down for months waiting for a replacement windshield to come.

I do implore PPG to get its act together with windshield production, not only on the Beechjet, but other models, too. Almost every jet with electric windshields have been struggling for years regarding lead times and pricing for windshields. I find it unacceptable for production issues to last this long on products that are certified.

Starter-Generators

I'm not sure what it is about the Beechjets, but I have had more starter-generator failures on them than any other type of aircraft I have flown. Usually, the failure mode is a total failure to operate when told to start the engine. I have seen some start-gens only last a couple hundred hours before failure, far below the 1800hr TBO. I have heard lots of rumors, but the most logical one is that the Beechjet start-gen just doesn't get the cooling airflow that it really needs. This is speculation, however.

I would be apt to blame a bad overhaul for this, but I have seen units from a vareity of overhaul facilities fail.

The worst part about start-gen failures is that they're unpredictable and pick the worst times and places. Multiple times I have been stranded in a Beechjet and had to order a start-gen exchange and get it shipped counter-to-counter to minimize downtime at an outstation location. The good news is that there is a healthy pool of exchange units in the rotable pool, so sourcing one at a competative price is usually very quick and easy.

Brakes and Tires

The XPR doesn't have thrust reversers, so you will go through brakes faster than a normal Beechjet. They're a rotable part with a healthy exchange market. Make sure to inspect pad wear duing the preflight and if you notice any potential issues with the braking system, get your mechanic on it ASAP.

Tires were a problem during COVID with lead times. The Beechjet mains can either be the Michelins or the Goodyears. The Goodyears are the better tire. We always keep a spare set in-stock just in case we have an event such as a flat spot that requires immediate replacement. To be honest, however, we get a surprisingly good life out of our tires.

We have had issues with a vibration in the nose gear on retraction. This gets resolved by tightinging up the nose wheel. The shimmy damper is also a part that might require replacement from time-to-time.

Pressurization

You might see your cabin VSI bounce up-and-down during descent, especially with the power pulled back. This is caused by a failing pneumatic relay in the pressurization system. This is located under the copilot seat.Conclusion

At the end of the day, the XPR is still just a Beechjet. A lot of what is discussed on this page is applicable to all Beechjets, not just the XPR.

The key to effective maintenance on the XPR (and perhaps any airplane) is to work with a trustworthy mechanic who is familiar with the nuances of the type of aircraft you have. XPR knowledge is pretty rare. This is to be expected on a small fleet airplane. You may need to invest in your preferred mechanic or shop to get up-to-speed on the XPR and its care-and-feeding.

When in doubt, all XPR owners are connected via a group on Facebook. Reach out to us and its bound to be someone in the group will have the answer you're looking for! If we don't know the answer, we know who to call at Textron who can figure out the answer for us!

----

Home -- Aircraft Sales -- Contact Us